Structural Steel

Product Details:

- Product Name Steel Products

- Steel Product Type Other

- Thickness 5mm Millimeter (mm)

- Shape Customized

- Surface Polished

- Application Construction

- Color Gray

- Click to View more

Structural Steel Price And Quantity

- 1000 Kilograms

- 81 INR/Kilograms

Structural Steel Product Specifications

- Gray

- Other

- Steel Products

- 5mm Millimeter (mm)

- Polished

- Customized

- Construction

Structural Steel Trade Information

- Standard, As per requirement,

- All India

- We are certified under the ISO 9001:2015 standard, with authorized distributor of Memorandum of Understanding (MoU) customer of the Steel Authority of India Ltd. (SAIL).

Product Description

Structural Steel refers to a category of steel used in the construction and manufacturing of structures like buildings, bridges, towers, industrial frameworks, and infrastructure projects. It is produced in various shapes, sizes, and grades, each designed for specific structural applications. Structural steel provides both strength and flexibility, making it an essential material in modern construction and manufacturing industries.

Key Characteristics of Structural Steel:

-

High Strength-to-Weight Ratio:

- Structural steel offers a high strength-to-weight ratio, providing significant strength without adding excessive weight. This makes it ideal for large-scale construction projects where strength and efficiency are essential.

-

Durability:

- Structural steel is highly durable and can withstand extreme loads and harsh environmental conditions. When properly coated or galvanized, it also offers resistance to corrosion, extending its lifespan, especially in outdoor or marine environments.

-

Malleability and Weldability:

- Structural steel is highly malleable and can be welded, cut, and shaped into various forms, such as I-beams, H-beams, channels, and angles. This makes it extremely versatile in fabrication.

-

Versatility:

- It is available in various shapes (such as I-beams, channels, angles, and flat bars) to meet the specific requirements of different applications. It is commonly used for both structural support and aesthetic elements in architecture.

-

Fire Resistance:

- Structural steel can maintain its structural integrity under high temperatures better than other materials like wood or concrete, though it may need fireproofing treatments for certain applications.

Common Types of Structural Steel:

-

Carbon Steel:

- This is the most common form of structural steel, made primarily of iron and carbon with small amounts of other elements.

- Types: Mild Steel, High Strength Low Alloy Steel (HSLA).

- Uses: I-beams, H-beams, angles, plates, and reinforcement bars in construction.

-

Alloy Steel:

- Alloy steel is steel that has had other elements (like manganese, chromium, nickel, and vanadium) added to improve certain properties such as strength, toughness, or corrosion resistance.

- Uses: Structural steel with high tensile strength used in heavy-duty applications such as mining equipment, construction cranes, and bridges.

-

Stainless Steel:

- Known for its corrosion resistance, stainless steel contains a significant amount of chromium (usually at least 10%), making it ideal for structures exposed to moisture or chemicals.

- Uses: Corrosion-resistant beams, support columns, and facades in marine environments or chemical plants.

-

High-Strength Low-Alloy Steel (HSLA):

- This is a stronger and lighter version of carbon steel, incorporating small amounts of additional alloying elements to improve mechanical properties.

- Uses: Structural applications in bridges, buildings, machinery, and vehicles.

-

Weathering Steel (Corten Steel):

- This type of steel is designed to form a stable, rust-like appearance when exposed to weather, providing a protective layer that resists further corrosion.

- Uses: Outdoor structures like bridges, sculptures, and architectural facades.

Common Forms of Structural Steel:

-

Beams:

- I-Beams: Known for their high strength and efficiency, I-beams are used extensively in building frames, bridges, and support structures.

- H-Beams: These beams have a wider flange than I-beams and are used in heavy-duty applications.

- UB and UC Beams: Universal Beams and Universal Columns used in large-scale structural projects.

-

Columns:

- Columns are vertical structural elements used to support the weight of the structure above them, commonly made from I-beams or hollow sections.

-

Angles:

- Angle Bars (also known as L-bars) are commonly used for reinforcement and in bracing structures like frames.

-

Channels:

- C-Channels are structural elements used for support, often combined with other shapes like beams or angles.

-

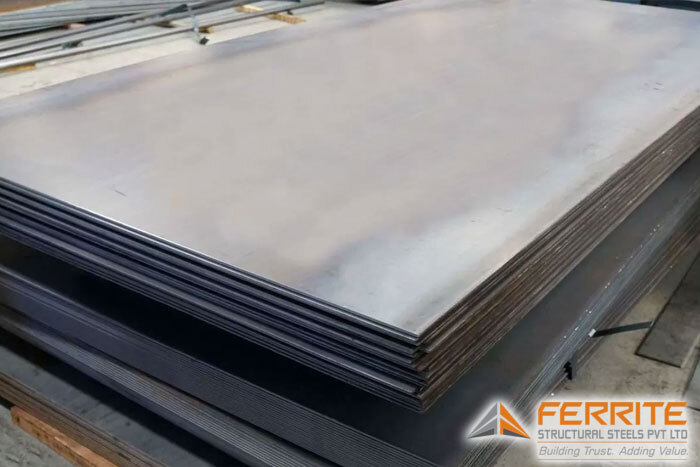

Plates:

- Steel plates are flat pieces used in various sizes and thicknesses for structural applications such as flooring, roofing, and walls.

-

Tubes & Pipes:

- Steel tubes (both round and rectangular), especially seamless steel tubes, are often used in heavy-duty industrial applications and frameworks.

Applications of Structural Steel:

-

Building Construction:

- Structural steel is used in the construction of commercial and residential buildings for load-bearing structures like frames, columns, roofs, and flooring.

-

Bridges:

- Steel is essential for the construction of highway and railway bridges, as it provides the strength and flexibility required for such large-scale projects.

-

Industrial and Factory Construction:

- Structural steel is used in the construction of warehouses, factories, plants, and storage facilities, where large, open spaces and high load-bearing capacities are required.

-

Infrastructure:

- Towers, masts, dams, stadiums, and power plants all rely on structural steel for their high-strength framework and support systems.

-

Shipbuilding and Offshore Structures:

- Steel plates and sections are used extensively in the construction of ships, offshore rigs, and maritime platforms.

-

Oil and Gas Industry:

- Structural steel is used in the construction of refineries, pipelines, and oil rigs, which require durability, strength, and resistance to corrosion.

Advantages of Structural Steel:

-

High Strength and Durability:

- Structural steel can withstand high loads, making it suitable for large-scale, heavy-duty applications.

-

Cost-Effective:

- It is a cost-effective material due to its high availability and versatility, providing an economical solution for structural projects.

-

Fast Construction:

- Pre-fabricated steel components can be assembled quickly on-site, reducing construction time and labor costs.

-

Flexibility in Design:

- Steels malleability allows for complex designs, enabling the creation of unique structures.

-

Recyclable:

- Steel is highly recyclable, making it an environmentally friendly choice for sustainable building projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS