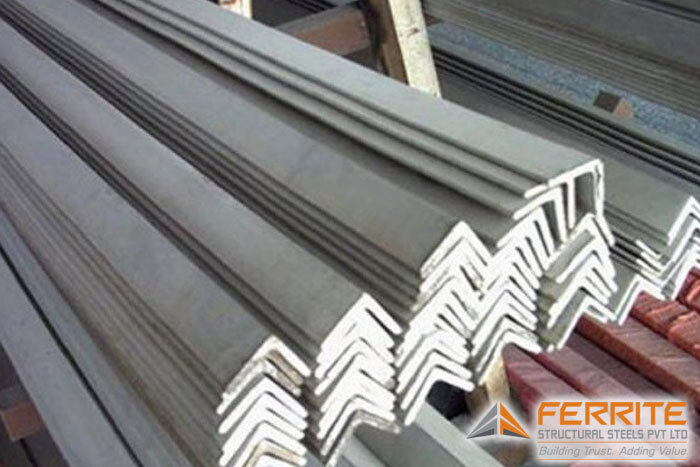

SS316L Beams

SS316L Beams Specification

- Product Name

- Steel Products

- Steel Type

- Mild Steel

- Grade

- ss

- Thickness

- 5mm Millimeter (mm)

- Shape

- Customized

- Surface

- Polished

- Application

- Construction

- Color

- Grey

SS316L Beams Trade Information

- Minimum Order Quantity

- 1 Ton

- Packaging Details

- Standard, As per requirement,

- Main Domestic Market

- All India

- Certifications

- We are certified under the ISO 9001:2015 standard, with authorized distributor of Memorandum of Understanding (MoU) customer of the Steel Authority of India Ltd. (SAIL).

About SS316L Beams

Beams made of SS316L

Austenitic grade SS316L which is used to makehighperformance stainless steel beams is renowned for its exceptionalstrength durability and resistance to corrosion These beams are frequentlyutilized in hightemperature chemical and maritime applications among otherareas where materials are subjected to harsh conditions

Important attributes and advantages

Better Resistance to Corrosion SS316L beams haveexceptional corrosion resistance particularly in abrasive acidic and marineenvironments

High Toughness and Strength Because of its exceptionalstrength due to its austenitic structure SS316L is perfect for heavydutystructural applications

Outstanding Resistance to Heat SS316L beams areappropriate for hightemperature settings because they retain their strengthand structural integrity even at high temperatures

Defending Against Chemical Attack Their resistance tochemical exposure makes them perfect for usage in refineries chemicalprocessing facilities and maritime applications

Both formability and weldability In demanding structuralapplications SS316L beams exceptional formability and weldability makefabrication and connecting simple

LongTerm Sturdiness Because of their exceptionallongterm endurance these beams require less upkeep and replacement incorrosive conditions

Lgrade or low carbon content The low carbon contentindicated by the L grade improves their resistance to sensitizationpreventing corrosion at the weld zones

Uses for SS316L Beams in Offshore and Marine Structures

Because of their remarkable resistance to corrosion inseawater settings they are utilized in shipbuilding offshore platforms andmaritime infrastructure

The industries of chemistry and petrochemistry used instorage tanks refineries and chemical processing facilities where it isessential to have resistance to harsh chemicals

Applications at High Temperatures Perfect for businessesthat must function in hot environments such power plants and

Price 72000 INR/ Ton

- Minimum Order Quantity

- 1 Ton

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Beam Category

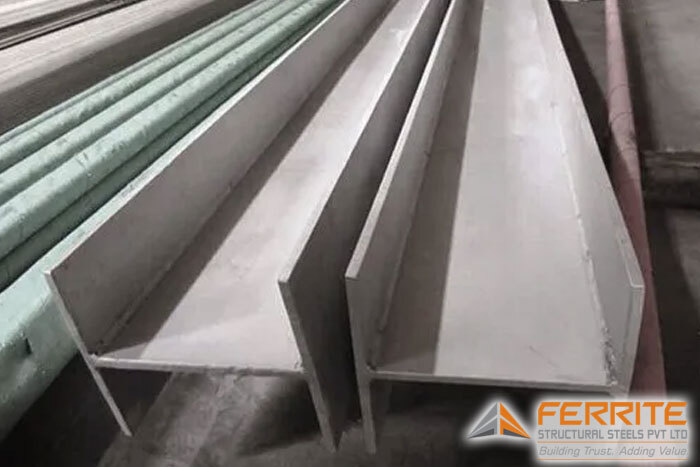

Stainless Steel H Beams

Minimum Order Quantity : 5 Tons

Color : steel , silver

Application : Construction

Product Name : Steel Products

Surface : Galvanized Surface Finish

Stainless Steel I Beams

Price 74 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Color : Gray

Application : Construction

Product Name : Steel Products

Surface : Polished

Stainless Steel W Beams

Price 66000 INR / Ton

Minimum Order Quantity : 1 Ton

Color : Gray

Application : Construction

Product Name : Steel Products

Surface : Polished

SS304L Beams

Price 56000 INR / Ton

Minimum Order Quantity : 1 Ton

Color : Silver

Application : Construction

Product Name : Steel Products

Surface : Polished

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free