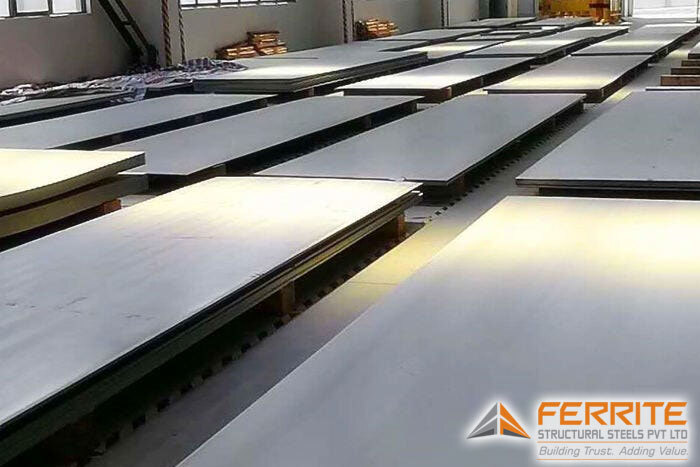

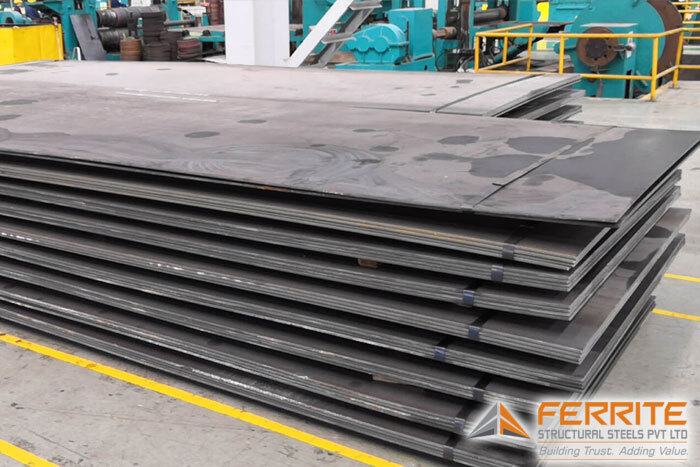

High Tensile Steel Plate

High Tensile Steel Plate Specification

- Coating Type

- Hot-rolled, galvanized, or as specified by customer

- Recyclable

- non-recyclable

- Product Name

- Steel Products

- Steel Type

- Stainless Steel

- Steel Product Type

- Steel Plates

- Grade

- E 250, E 350

- Thickness

- 3 mm , customized Millimeter (mm)

- Surface

- Polished

- Application

- Construction

- Dimension (L*W*H)

- 75 x 40 to 300 x 90 Millimeter (mm)

- Color

- Silver

High Tensile Steel Plate Trade Information

- Minimum Order Quantity

- 5 Tons

- Packaging Details

- Standard, As per requirement,

- Main Domestic Market

- All India

- Certifications

- Ferrite Structural Steels Pvt Ltd, established in 2004 in Mumbai, India, is a privately held company specializing in the production and supply of high-quality special steel structures. With a lineage of over 30 years in the steel industry, we have forged strong relationships with leading steel manufacturers and suppliers across India.

About High Tensile Steel Plate

-

High Tensile Steel Plates

High Tensile Steel Plates are engineered for applications that require superior strength durability and resistance to wear and impact These plates are manufactured using advanced rolling techniques and alloy compositions to ensure higher yield and tensile strength compared to standard mild steel plates Ideal for heavyduty structural and loadbearing applications high tensile plates are widely used in construction mining defense shipbuilding and heavy machinery industries

Key Features

High Yield Tensile Strength

Designed to withstand heavy stress without deformation or failure

Good Weldability Formability

Despite the high strength these plates can be easily fabricated

Corrosion Resistance

Enhanced resistance to rust and weathering when treated or coated

Cost Efficient for Structural Use

Less material is needed for the same loadbearing capacity reducing overall weight and cost

Applications

Bridges flyovers highrise buildings

Cranes booms truck frames

Pressure vessels and boilers

Offshore structures and shipbuilding

Mining and earthmoving equipment

Railway wagons and coaches

Wind towers and solar infrastructure

Price 86000 INR/ Ton

- Minimum Order Quantity

- 5 Tons

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mild Steel Plate Category

IS2062 E350 C/BR/BO

Price 52 INR / Kilograms

Minimum Order Quantity : 1 Ton Kilograms

Color : Steel , Silver

Product Name : Steel Products

Shape : Customized

Application : Construction

Steel Plates

Price 78 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Color : Gray

Product Name : Steel Products

Shape : Customized

Application : Construction

S275JR Plate

Price 56 INR / Kilograms

Minimum Order Quantity : 1 Ton Kilograms

Color : Steel , Silver

Product Name : Steel Products

Shape : Customized

Application : Construction

Carbon Steel Plates

Price 550 INR / Piece

Minimum Order Quantity : 50 Inches

Color : silver

Product Name : Stainless Steel Products

Shape : Plate

Application : Construction

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free