Galvanized Steel Structures

Galvanized Steel Structures Specification

- Coating Type

- Hot-rolled, galvanized, or as specified by customer

- Recyclable

- non-recyclable

- Product Name

- Steel Products

- Steel Type

- Mild Steel

- Steel Product Type

- Other

- Thickness

- 5mm Millimeter (mm)

- Shape

- Customized

- Surface

- Polished

- Application

- Construction

- Dimension (L*W*H)

- 75 x 40 to 300 x 90 Millimeter (mm)

- Color

- Silver

Galvanized Steel Structures Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Packaging Details

- Standard, As per requirement

- Main Domestic Market

- All India

- Certifications

- Ferrite Structural Steels Pvt Ltd, established in 2004 in Mumbai, India, is a privately held company specializing in the production and supply of high-quality special steel structures. With a lineage of over 30 years in the steel industry, we have forged strong relationships with leading steel manufacturers and suppliers across India.

About Galvanized Steel Structures

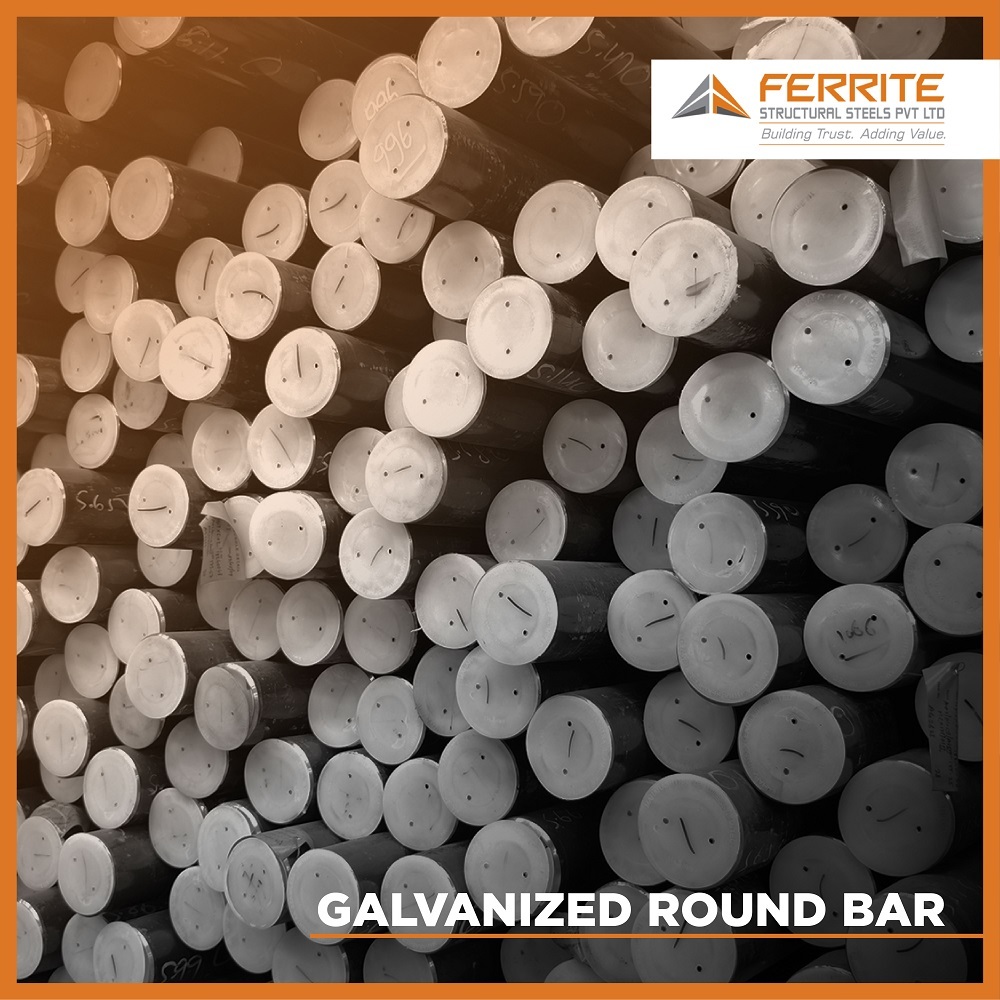

Galvanized Steel Structures

Galvanized Steel Structures are robust and corrosion-resistant frameworks used across various industries for their superior durability and long-lasting performance. These structures are fabricated from high-grade steel that is hot-dip galvanized, offering enhanced resistance against rust, moisture, and harsh environmental conditions.

Key Features:

-

Corrosion Resistance: Zinc coating provides long-term protection against rust and weather

-

Superior Strength: Withstands heavy loads and tough working conditions

-

Maintenance-Free: No need for frequent painting or coatings

-

Quick Installation: Prefabricated options reduce construction time

-

Customizable Design: Tailored to project specifications (shape, size, and load-bearing capacity)

-

Compliant with Standards: Designed as per IS, ASTM, or BS standards

Applications:

-

Pre-engineered buildings and industrial sheds

-

Transmission line towers and poles

-

Solar panel mounting structures

-

Railway and highway infrastructure

-

Cold storage and agricultural buildings

-

Telecom towers and lighting masts

Galvanized Steel Structures are available in both standard and custom-built configurations, offered in tubular, angle, I-beam, H-beam, and C-channel profiles.

Price 86 INR/ Square Foot

- Minimum Order Quantity

- 100 Square Foots

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS