HEAA Beams (High-Efficiency American Advanced Beams)

HEAA Beams (High-Efficiency American Advanced Beams) Specification

- Coating Type

- Hot-rolled, galvanized, or as specified by customer

- Recyclable

- non-recyclable

- Product Name

- Steel Products

- Steel Type

- Structural Steel

- Steel Product Type

- Steel Bars

- Grade

- Premium

- Thickness

- 3 mm to 25 mm Millimeter (mm)

- Shape

- Bar

- Surface

- Smooth Surface Finish

- Application

- Construction

- Dimension (L*W*H)

- 75 x 40 mm to 400 x 100 mm (or custom sizes)

- Color

- Grey

HEAA Beams (High-Efficiency American Advanced Beams) Trade Information

- Minimum Order Quantity

- 3 Tons

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- Ton

- Packaging Details

- Standard, As per requirement,

- Main Domestic Market

- All India

- Certifications

- We are certified under the ISO 9001:2015 standard, with authorized distributor of Memorandum of Understanding (MoU) customer of the Steel Authority of India Ltd. (SAIL).

About HEAA Beams (High-Efficiency American Advanced Beams)

HEAA Beams, short for High-Efficiency American Advanced Beams, are a type of structural steel beam designed for advanced load-bearing applications. These beams feature parallel flange geometry with optimized dimensions, allowing them to deliver superior structural support. They are widely used in industrial, commercial, and residential construction, offering excellent strength-to-weight ratios and versatility in application.

Key Features

-

Advanced Design

- Optimized for efficient weight distribution and structural stability.

-

High Load Capacity

- Capable of supporting heavy vertical and lateral loads with ease.

-

Parallel Flange Geometry

- Ensures uniform load-bearing and simplifies connections in construction.

-

Durable Construction

- Manufactured from premium-grade materials with superior resistance to stress and deformation.

-

Compliance with Standards

- Designed according to ASTM, AISC, and other global standards.

Specifications

-

Grades:

- Common grades include ASTM A36, ASTM A572, A992, and A514.

-

Dimensions:

- Customized flange width, web height, and thickness options available.

-

Length:

- Typically supplied in lengths of 6m, 9m, 12m, and custom sizes upon request.

-

Finish Options:

- Bare, painted, or hot-dip galvanized for enhanced durability and corrosion resistance.

Applications

-

Industrial Construction

- Ideal for factories, warehouses, and industrial plants.

-

Commercial Buildings

- Used in the framework of malls, office complexes, and parking garages.

-

Infrastructure Development

- Common in bridges, highways, and railway stations.

-

Heavy Equipment Support

- Suitable for crane girders, machine bases, and support structures.

-

Energy Projects

- Widely used in renewable energy projects, such as wind turbines and solar farms.

Advantages

-

High Strength and Durability

- Designed to withstand extreme loads and harsh environments.

-

Cost-Effective Solution

- Provides excellent performance while minimizing material usage.

-

Ease of Fabrication

- Simplifies cutting, welding, and bolting for faster assembly.

-

Corrosion Resistance

- Galvanized options ensure longevity even in moisture-prone areas.

-

Eco-Friendly Construction

- Manufactured from recyclable materials, contributing to sustainable building practices.

- Minimum Order Quantity

- 3 Tons

- Supply Ability

- 7680903 Tons

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mild Steel Beams Category

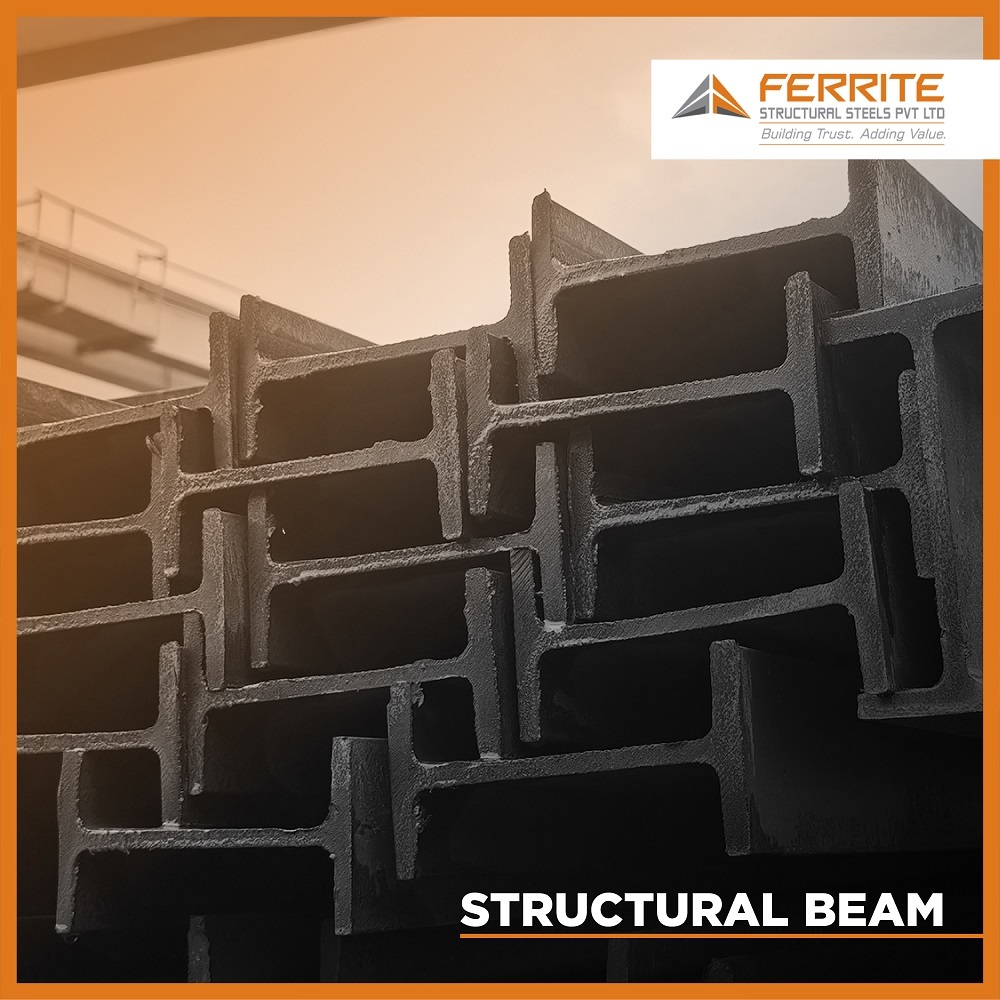

Structural Beams

Price 85 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Color : Silver

Steel Product Type : Other

Steel Type : Mild Steel

Product Name : Steel Products

Structural Steel H Beam

Price 75000 INR / Ton

Minimum Order Quantity : 1 Ton

Color : Silver

Steel Product Type : Other

Steel Type : Mild Steel

Product Name : Steel Products

MS Roof Beam

Price 80000 INR / Kilograms

Minimum Order Quantity : 1 Ton

Color : Steel , Silver

Steel Product Type : Steel Bars

Steel Type : Mild Steel

Product Name : Steel Products

Mild Steel H Beam

Price 54000 INR / Ton

Minimum Order Quantity : 1 Ton

Color : Gray

Steel Product Type : Other

Steel Type : Mild Steel

Product Name : Steel Products

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free