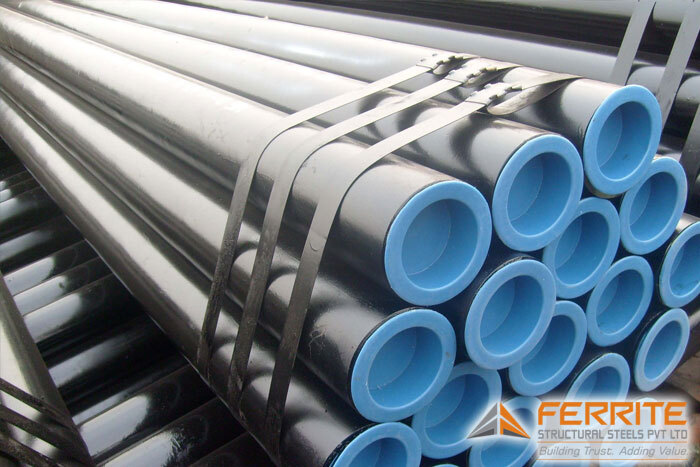

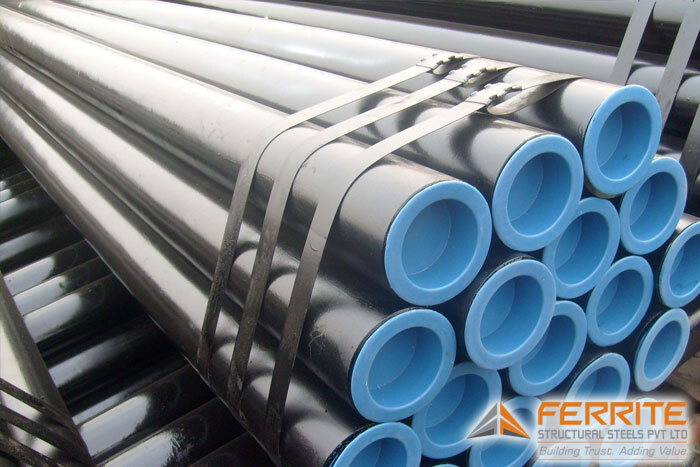

Seamless Mild Steel Tube

उत्पाद विवरण:

- कोटिंग का प्रकार Galvanized

- पुन: उपयोग करने योग्य non-recyclable

- प्रोडक्ट का नाम

- स्टील का प्रकार

- स्टील उत्पाद का प्रकार

- ग्रेड SS304

- शेप

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- SS304

- Galvanized

- Polished

- Black

- non-recyclable

व्यापार सूचना

- Standard, As per requirement

- We are certified under the ISO 9001:2015 standard, with authorized distributor of Memorandum of Understanding (MoU) customer of the Steel Authority of India Ltd. (SAIL).

उत्पाद वर्णन

Seamless steel tubes are hollow steel products without welded joints offering superior strength and reliability These tubes are made using hot rolling or cold drawing processes making them highly durable and versatile for a wide range of industrial applications

Key Features

Seamless Construction

No welded seams eliminate weak points ensuring uniform strength throughout

High Pressure Temperature Resistance

Suitable for use in highpressure environments and extreme temperature conditions

Smooth Interior Surface

Ideal for fluid and gas flow with minimal friction

Corrosion Resistance

Enhanced performance when made of stainless steel or with protective coatings

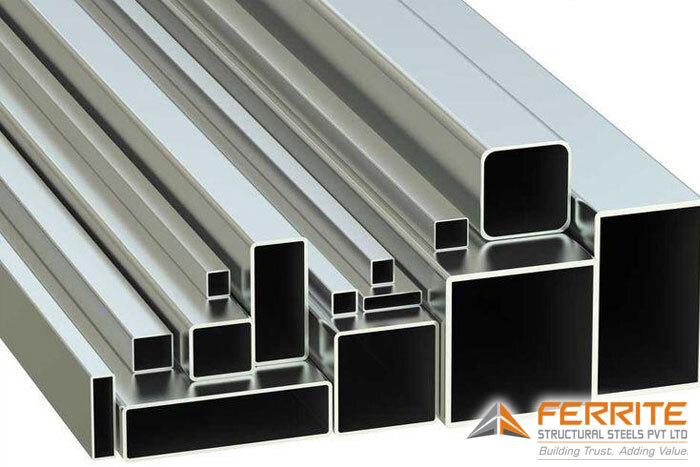

Versatile Sizes Thicknesses

Customizable to specific industrial requirements

Applications

Oil Gas Used in pipelines drilling tools and offshore structures

Automotive For manufacturing drive shafts suspension components and precision tubes

Boilers Heat Exchangers Withstanding hightemperature steam and fluids

Construction Loadbearing structures scaffolding and reinforcement

Mechanical Systems Hydraulic and pneumatic systems cylinder barrels

Power Generation Tubes for nuclear thermal and hydroelectric plants

Advantages

Uniform mechanical properties

High dimensional accuracy

Resistance to cracking and breaking under stress

Longer lifespan compared to welded pipes

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें