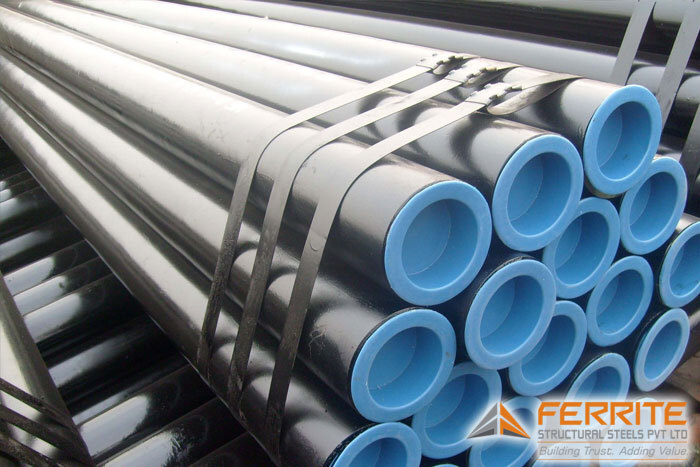

Seamless Tube

65 आईएनआर/Kilograms

उत्पाद विवरण:

- कोटिंग का प्रकार Hot-rolled, galvanized, or as specified by customer

- व्यास 4 inches

- पुन: उपयोग करने योग्य non-recyclable

- प्रोडक्ट का नाम

- स्टील का प्रकार

- स्टील उत्पाद का प्रकार

- मोटाई 1 inch-2 inch

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1 Ton

उत्पाद की विशेषताएं

- 1 inch-2 inch

- 4 inches

- Hot-rolled, galvanized, or as specified by customer

- non-recyclable

- Steel , Silver

- 4 inches

- Painted, galvanized, or standard mill finish

व्यापार सूचना

- Standard, As per requirement,

- We are certified under the ISO 9001:2015 standard, with authorized distributor of Memorandum of Understanding (MoU) customer of the Steel Authority of India Ltd. (SAIL).

उत्पाद वर्णन

Seamless TubeA seamless tube is a type of tube that is formed without any welds or seams, ensuring high strength and reliability. These tubes are created by extruding metal billets into a hollow shape, and they are ideal for high-pressure and high-temperature applications. The absence of a welded joint ensures that seamless tubes have enhanced durability and resistance to leaks and cracks.Key Features and BenefitsHigh Strength and DurabilitySeamless tubes are strong and have high tensile strength, making them ideal for demanding applications where reliability is crucial.Uniform Wall ThicknessThese tubes have uniform wall thickness, ensuring consistent performance and structural integrity across the tube length.Corrosion ResistanceThey are resistant to corrosion, especially when made from materials like stainless steel, making them suitable for harsh environments such as chemical, marine, and industrial applications.Pressure ResistanceDue to their manufacturing process, seamless tubes can withstand higher pressure compared to welded tubes, making them ideal for high-pressure applications like pipelines and heat exchangers.Smooth SurfaceThe internal surface of a seamless tube is smooth and free from any welds, reducing friction and making them ideal for fluid and gas flow applications.ApplicationsOil and Gas IndustrySeamless tubes are widely used for pipelines, pressure vessels, and fluid transportation systems due to their ability to handle high pressures and harsh conditions.Automotive IndustryUsed in manufacturing engine components, hydraulic lines, and exhaust systems, seamless tubes are valued for their durability and strength.Aerospace and AviationEssential in aerospace applications, including fuel and hydraulic systems, due to their high strength-to-weight ratio and ability to withstand extreme temperatures.Heat Exchangers and BoilersSeamless tubes are commonly used in heat exchangers and boilers for their ability to handle high-temperature fluids under pressure.FAQs of Seamless Tube:

Q: What is the steel type used in the Seamless Tube?

A: The Seamless Tube is made of Stainless Steel.Q: What are the coating types available for the Seamless Tube?

A: The coating types available for the Seamless Tube include hot-rolled, galvanized, or as specified by the customer.Q: What is the thickness range of the Seamless Tube?

A: The Seamless Tube comes in thickness ranging from 1 inch to 2 inches.Q: What applications is the Seamless Tube suitable for?

A: The Seamless Tube is suitable for construction applications.Q: Is the Seamless Tube recyclable?

A: The Seamless Tube is non-recyclable.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

Industrial Pipes अन्य उत्पाद

“हम स्थानीय क्षेत्रों में ही काम कर रहे हैं।

”

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें